Shallow Thoughts : tags : arduino

Akkana's Musings on Open Source Computing and Technology, Science, and Nature.

Sat, 10 Mar 2018

![[Intel Galileo Gen2 by Mwilde2 on Wikimedia commons]](https://upload.wikimedia.org/wikipedia/commons/thumb/f/f8/IntelGalileoGen2.png/320px-IntelGalileoGen2.png) Our makerspace got a donation of a bunch of Galileo gen2 boards from Intel

(image

from Mwilde2

on Wikimedia commons).

Our makerspace got a donation of a bunch of Galileo gen2 boards from Intel

(image

from Mwilde2

on Wikimedia commons).

The Galileo line has been discontinued, so there's no support and

no community, but in theory they're fairly interesting boards.

You can use a Galileo in two ways: you can treat it

like an Arduino, after using the Arduino IDE to download a

Galileo hardware definition since they're not Atmega chips. They

even have Arduino-format headers so you can plug in an Arduino shield.

That works okay (once you figure out that you need to download

the Galileo v2 hardware definitions, not the regular Galileo).

But they run Linux under the hood, so you can also use them as a

single-board Linux computer.

Serial Cable

The first question is how to talk to the board. The documentation is terrible,

and web searches aren't much help because these boards were never

terribly popular. Worse, the v1 boards seem to have been more widely

adopted than the v2 boards, so a lot of what you find on the web

doesn't apply to v2. For instance, the v1 required a special serial cable

that used a headphone jack as its connector.

Some of the Intel documentation talks about how you can load a special

Arduino sketch that then disables the Arduino bootloader and instead

lets you use the USB cable as a serial monitor. That made me nervous:

once you load that sketch, Arduino mode no longer works until you

run a command on Linux to start it up again. So if the sketch doesn't

work, you may have no way to talk to the Galileo.

Given the state of the documentation I'd already struggled with for

Arduino mode, it didn't sound like a good gamble. I thought a real

serial cable sounded like a better option.

Of course, the Galileo documentation doesn't tell you what needs to

plug in where for a serial cable. The board does have a standard FTDI

6-pin header on the board next to the ethernet jack, and the labels on

the pins seemed to correspond to the standard pinout on my Adafruit

FTDI Friend: Gnd, CTS, VCC, TX, RX, RTS. So I tried that first, using

GNU screen to connect to it from Linux just like I would a Raspberry

Pi with a serial cable:

screen /dev/ttyUSB0 115200

Powered up the Galileo and sure enough, I got boot messages and was

able to log in as root with no password. It annoyingly forces orange

text on a black background, making it especially hard to read on

a light-background terminal, but hey, it's a start.

Later I tried a Raspberry Pi serial cable, with just RX (green), TX (white)

and Gnd (black) -- don't use the red VCC wire since the Galileo is already

getting power from its own power brick -- and that worked too. The Galileo

doesn't actually need CTS or RTS. So that's good: two easy ways to talk to

the board without buying specialized hardware. Funny they didn't bother

to mention it in the docs.

Blinking an LED from the Command Line

Once connected, how do you do anything? Most of the

Intel

tutorials on Linux are useless, devoting most of their space

to things like how to run Putty on Windows and no space at all to

how to talk to pins. But I finally found a

discussion thread

with a Python example for Galileo. That's not immediately helpful

since the built-in Linux doesn't have python installed (nor gcc,

natch). Fortunately, the Python example used files in /sys

rather than a dedicated Python library;

we can access /sys files just as well from the shell.

Of course, the first task is to blink an LED on pin 13. That

apparently corresponds to GPIO 7 (what are the other arduino/GPIO

correspondences? I haven't found a reference for that yet.) So you

need to export that pin (which creates /sys/class/gpio/gpio7

and set its direction to out. But that's not enough: the

pin still doesn't turn on when you

echo 1 > /sys/class/gpio/gpio7/value. Why not?

I don't know, but the Python script exports three other pins --

46, 30, and 31 -- and echoes 0 to 30 and 31. (It does this without

first setting their directions to out, and if you try

that, you'll get an error, so I'm not convinced the Python script

presented as the "Correct answer" would actually have worked. Be warned.)

Anyway, I ended up with these shell lines as

preparation before the Galileo can actually blink:

# echo 7 >/sys/class/gpio/export

# echo out > /sys/class/gpio/gpio7/direction

# echo 46 >/sys/class/gpio/export

# echo 30 >/sys/class/gpio/export

# echo 31 >/sys/class/gpio/export

# echo out > /sys/class/gpio/gpio30/direction

# echo out > /sys/class/gpio/gpio31/direction

# echo 0 > /sys/class/gpio/gpio30/value

# echo 0 > /sys/class/gpio/gpio31/value

And now, finally, you can control the LED on pin 13 (GPIO 7):

# echo 1 > /sys/class/gpio/gpio7/value

# echo 0 > /sys/class/gpio/gpio7/value

or run a blink loop:

# while /bin/true; do

> echo 1 > /sys/class/gpio/gpio7/value

> sleep 1

> echo 0 > /sys/class/gpio/gpio7/value

> sleep 1

> done

Searching Fruitlessly for a "Real" Linux Image

All the Galileo documentation is emphatic that you should download

a Linux distro and burn it to an SD card rather than using the Yocto

that comes preinstalled. The preinstalled Linux apparently has no

persistent storage, so not only does it not save your Linux programs,

it doesn't even remember the current Arduino sketch.

And it has no programming languages and only a rudimentary busybox shell.

So finding and downloading a Linux distro was the next step.

Unfortunately, that mostly led to dead ends. All the official Intel

docs describe different download filenames, and they all point to

generic download pages that no longer include any of the filenames

mentioned. Apparently Intel changed the name for its Galileo images

frequently and never updated its documentation.

After forty-five minutes of searching and clicking around,

I eventually found my way to

Intel® IoT Developer Kit Installer Files,

which includes sizable downloads with names like

- iss-iot-linux_12-09-16.tar.bz2 (324.07 MB),

- intel-iot-yocto.tar.xz (147.53 MB),

- intel-iot-wrs-pulsar-64.tar.xz (283.86 MB),

- intel-iot-wrs-32.tar.xz (386.16 MB), and

- intel-iot-ubuntu.tar.xz (209.44 MB)

From the size, I suspect those are all Linux images. But what are they

and how do they differ? Do any of them still have working repositories?

Which ones come with Python, with gcc, with GPIO support,

with useful development libraries? Do any of them get security updates?

As far as I can tell, the only way to tell is to download each image,

burn it to a card, boot from it, then explore the filesystem

trying to figure out what distro it is and how to try updating it.

But by this time I'd wasted three hours and gotten no

further than the shell commands to blink a single LED, and I ran out of

enthusiasm. I mean, I could spend five more hours on this, try several

of the Linux images, and see which one works best. Or I could spend

$10 on a Raspberry Pi Zero W that has abundant documentation,

libraries, books, and community howtos. Plus wi-fi, bluetooth and HDMI,

none of which the Galileo has.

Arduino and Linux Living Together

So that's as far as I've gone. But I do want to note

one useful thing I stumbled upon while searching

for information about Linux distributions:

Starting Arduino

sketch from Linux terminal shows how to run an Arduino sketch

(assuming it's already compiled) from Linux:

sketch.elf /dev/ttyGS0 &

It's a fairly cool option to have. Maybe one of these days, I'll pick

one of the many available distros and try it.

Tags: hardware, linux, intel, galileo, arduino, maker

[

13:54 Mar 10, 2018

More hardware |

permalink to this entry |

]

Sat, 16 Dec 2017

Playing with the

ATtiny85

I was struck by how simple the circuit was.

Sure, I'd made a

homemade

Arduino on a breadboard;

but with the crystal and all the extra capacitors and resistors it ends

up seeming like a lot of parts and wires.

If an ATtiny can use a built-in clock and not need all those extra

parts, couldn't I use an Atmega328 the same way?

![[Circuit for Atmega328 on breadboard with ISP]](http://shallowsky.com/blog/images/arduino/bare-atmega-breadboard-isp_bb.jpg) Why, yes, as it turns out. But there are a few tricks.

Why, yes, as it turns out. But there are a few tricks.

Wire it

Wiring a bare Atmega chip is easy.

You'll want to keep a good pinout diagram handy, like this

Arduino

ATmega328 Pinout from HobbyTronics.

For the initial wiring, all you need is

two power and two ground lines, the pins marked - and +,

plus a pullup resistor on RST (something large, like 10kΩ).

The excellent tutorial

From

Arduino to a Microcontroller on a Breadboard is a good guide

if you need additional details: the third section

shows a circuit without external clock.

Add an LED and resistor on pin 13 (atmega pin 19, called SCK) so

you can test it using a blink program.

Now you need to set up the software.

Set up a hardware profile for a bare Arduino

To program it with the Arduino libraries,

you'll need a hardware definition for an atmega328 chip

with an internal clock. I used the download

from the last section of the excellent tutorial,

From

Arduino to a Microcontroller on a Breadboard. (Keep that page

up: it has good wiring diagrams.)

For Arduino 1.8.5, download breadboard-1-6-x.zip and unpack it

in your ~/sketchbook/hardware/ directory, making a directory

there called breadboard. Then you'll need to make one change:

the 1.6 directory is missing a file called pins_arduino.h",

so if you try to compile with this hardware definition, you'll get

an error like:

mkdir -p build-atmega328bb-atmega328

/usr/local/share/arduino/hardware/tools/avr/bin/avr-g++ -x c++ -include Arduino.h -MMD -c -mmcu=atmega328p -DF_CPU=8000000L -DARDUINO=185 -DARDUINO_ARCH_AVR -D__PROG_TYPES_COMPAT__ -I/usr/local/share/arduino/hardware/arduino/avr/cores/arduino -I/home/akkana/sketchbook/hardware/breadboard/avr/variants/standard -Wall -ffunction-sections -fdata-sections -Os -fpermissive -fno-exceptions -std=gnu++11 -fno-threadsafe-statics -flto blink.ino -o build-atmega328bb-atmega328/blink.ino.o

In file included from :0:0:

/usr/local/share/arduino/hardware/arduino/avr/cores/arduino/Arduino.h:257:26: fatal error: pins_arduino.h: No such file or directory

#include "pins_arduino.h"

^

compilation terminated.

/usr/share/arduino/Arduino.mk:1251: recipe for target 'build-atmega328bb-atmega328/blink.ino.o' failed

make: *** [build-atmega328bb-atmega328/blink.ino.o] Error 1

The problem is that it's including these directories:

-I/usr/local/share/arduino/hardware/arduino/avr/cores/arduino

-I/home/akkana/sketchbook/hardware/breadboard/avr/variants/standard

but the actual file is in:

/usr/local/share/arduino/hardware/arduino/avr/variants/standard/pins_arduino.h

You can fix that by making a link from the "standard" directory in your

Arduino install to breadboard/avr/variants/standard. On Linux, that would

be something like this (Mac and Windows people can substitute their

local equivalents):

ln -s /usr/local/share/arduino/hardware/arduino/avr/variants/standard ~/sketchbook/hardware/breadboard/avr/variants/

Now your hardware definition should be ready to go. To check, fire up

the IDE and look in Tools->Board for

ATmega328 on a breadboard (8 MHz internal clock).

Or if you use Arduino-mk, run

ALTERNATE_CORE=breadboard make show_boards

and make sure it lists

atmega328bb ATmega328 on a breadboard (8 MHz internal clock).

Reprogram the Fuses and Bootloader for an Internal Clock

The next trick is that an Atmega chip programmed with the Arduino

bootloader is also fused to use an external, 16MHz clock.

If you wire it to use its internal 8MHz clock, you won't be

able to talk to it with either an ISP or FTDI.

You'll definitely run into this if you pull the CPU out of an Arduino.

But even if you buy new chips you may see it:

many Atmega328s come pre-programmed with the Arduino bootloader.

After all, that's what most people want.

The easiest way to reprogram the fuses is to use the hardware

definition you just installed to burn a new bootloader, which resets

the fuse settings at the same time. So you need an In-System

Programmer, or ISP. You can use an Arduino as an ISP, but I'm told

that this tends to be flaky and isn't recommended. After I had

problems using an Arduino I ordered a cheap USBtinyUSP, which works

fine.

Regardless of which ISP you use, if you wire up your atmega without

an external clock when it's fused for one, you won't be able to burn a

bootloader. A typical error:

[ ... ]

Reading | ################################################## | 100% 0.02s

avrdude: Device signature = 0x000000 (retrying)

Error while burning bootloader.

Reading | ################################################## | 100% 0.02s

avrdude: Device signature = 0x000000

avrdude: Yikes! Invalid device signature.

Double check connections and try again, or use -F to override

this check.

The solution is to burn the bootloader using an external clock.

You can add a crystal and two capacitors to your breadboard circuit

if you have them.

If not, an easy solution is to pull the chip out of the breadboard,

plug it into the socket in an Arduino and burn it there.

(Note: if you're using an Arduino as your ISP, you'll need a second

Arduino.)

Plug your ISP into the Arduino's ISP header: on an Uno, that's the

header labeled ICSP at the end of the chip farthest away from the USB

plug. It's a six-pin connector (2x3), it's easy to plug in backward

and you can't depend on either the Arduino's header or the ISP's cable

being labeled as to direction; if in doubt, use a multimeter in

continuity mode to see which pin is ground on each side, then make

sure those pins match. Once you're sure, mark your connector somehow

so you'll know next time.

In the Arduino IDE, set Tools->Board to

ATmega328 on a breadboard (8 MHz internal clock),

set Programmer to whatever ISP you're using.

then run Tools->Burn Bootloader.

If you're using Arduino-mk instead of the IDE,

set up a Makefile that looks like this:

ALTERNATE_CORE = breadboard

BOARD_TAG = atmega328bb

ISP_PROG = usbtiny

include /usr/local/share/Arduino-Makefile/Arduino.mk

Substitute your ISP, if different, and your location for Arduino.mk.

Then type

make burn_bootloader

Program it

Once you're wired, you should be able to program it either with an

FTDI board or an ISP, as I discussed in

homemade

Arduino, Part 1.

You should be able to use your minimal Atmega328 to

run anything you can run on a normal Arduino (albeit at half the

clock speed).

I plan to make a little board with a ZIF socket and connectors for

both the USBtinyISP and the FTDI Friend so I don't have to plug in

all those wires again each time.

Tags: hardware, arduino, maker

[

13:14 Dec 16, 2017

More hardware |

permalink to this entry |

]

Sat, 09 Dec 2017

There are lots of tutorials around for building an Arduino on a

breadboard, using an Atmega328 (or the older 168) chip, a crystal,

a few capacitors and resistors and a power supply.

It's a fun project that every Arduino hacker should try at least once.

But while there are lots of instructions on how to wire up a breadboard

Arduino, most instructions on how to program one are confusing and incomplete.

Of course, you can program your Atmega chip while it's in an Arduino,

then unplug it from the Arduino's socket and move it to the

breadboard. But what a hassle! It's so more convenient to leave the chip

in the breadboard while you test new versions of the code. And you can,

in two different ways: with FTDI, which uses the Arduino bootloader,

or with an ISP, which doesn't.

Either way, start by downloading a good pinout diagram for the

Atmega328 chip. I use this one: the

Arduino

ATmega328 Pinout from HobbyTronics, which is very compact yet does a

good job of including both the mappings to Arduino digital and analog

pins and the functions like RX, TX, MOSI and MISO you'll need for

programming the chip.

Load Programs with FTDI

![[Circuit for Atmega328 on breadboard with FTDI friend]](http://shallowsky.com/blog/images/arduino/bare-atmega-breadboard-ftdi_bb.jpg) An FTDI board is a little trickier to wire than an ISP, but it's

less risky because it loads the code the same way an Arduino would,

so you don't overwrite the bootloader and you

can still put your chip back into an Arduino if things go wrong.

So let's start with FTDI.

An FTDI board is a little trickier to wire than an ISP, but it's

less risky because it loads the code the same way an Arduino would,

so you don't overwrite the bootloader and you

can still put your chip back into an Arduino if things go wrong.

So let's start with FTDI.

I use an

Adafruit "FTDI Friend", but there are lots of similar

FTDI boards from Sparkfun

and other vendors. They have six outputs,

but you'll need only five of those. Referring to your Atmega pinout,

wire up power, ground, TX, and RX. For some FTDI boards you may need

pullup resistors on the TX and RX lines; I didn't need them.

Now you have four pins connected.

Wiring the reset line is more complicated because it requires a

0.1μF capacitor. A lot of tutorials don't mention the capacitor,

but it didn't work for me without one.

Connect from RTS on the FTDI board, through the

0.1μF cap, to the RST line.

A 0.1μF capacitor is an electrolytic cap with a positive and a

negative lead, but the few online tutorials that even mention the

capacitor don't bother to say which side is whick. I connected the

FTDI friend to the cap's negative lead, and the positive lead to the

Atmega chip, and it worked.

You may also need a pullup on that RST/RTS line: a resistor

around 10kΩ from the RST pin 1 of the atmega chip to the 5v power line.

Note: the Fritzing diagram here shows pullup resistors on RST, TX

and RX. You may not need any of them.

Incidentally, RST stands for "reset", while RTS stands for "Ready To

Send"; they're not meant as anagrams of each other. The remaining pin

on the FTDI friend, CTS, is "Clear To Send" and isn't needed for an

Arduino.

Once the wiring is ready, plug in the FTDI board, check to make sure

Port is set to whatever port the FTDI board registered,

and try uploading a program as if you were uploading to a normal Arduino Uno.

And cross your fingers. If it doesn't work, try fiddling with pullups

and capacitor values.

Load Programs with an ISP

![[Circuit for Atmega328 on breadboard with ISP]](http://shallowsky.com/blog/images/arduino/bare-atmega-breadboard-isp_bb.jpg) An In-System Programmer, or ISP, writes programs straight to the chip,

bypassing (and overwriting) the Arduino bootloader. You can also use

an ISP to burn a new bootloader and reprogram the fuses on your

Arduino, to change parameters like the clock rate. (More on that in Part 2.)

An In-System Programmer, or ISP, writes programs straight to the chip,

bypassing (and overwriting) the Arduino bootloader. You can also use

an ISP to burn a new bootloader and reprogram the fuses on your

Arduino, to change parameters like the clock rate. (More on that in Part 2.)

You can use an

Arduino as an ISP, but it's somewhat unreliable and

prone to unexplained errors. A dedicated ISP isn't expensive, is

easier to wire and is more likely to work. A common type of ISP is

called a "USBtinyISP", and you can buy one from vendors like

Sparkfun or

Adafruit,

or search for usbtinyisp on sites like ebay or aliexpress.

Update: I've been curious about this flakiness: why does "Arduino as ISP"

work fine for some people and utterly fail for others? One person I asked

thought it had to do with the way Arduinos reset the RESET line whenever

the serial port is opened: so RESET gets toggled at the wrong time as

the bootloader code is being transferred.

An alternate method that may get around this is

Gammon Forum's

Atmega bootloader programmer, which includes the bootloader bits

as part of the code so it doesn't need to re-open the serial port.

Someone else says a 10 uF capacitor between reset and ground should

prevent that from happening; and another person says it should be a

100nF capacitor between RST on the programmer and RST on the AVR-chip

plus a 10k pullup resistor,

Most Arduino-as-ISP tutorials, including the official ones on arduino.cc,

don't mention either capacitors or pullups,

so that may explain why the method works for some people and not others.

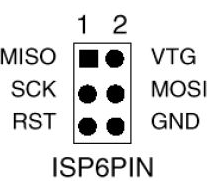

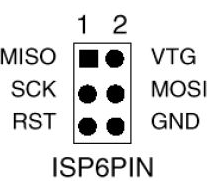

ISPs typically use a six-pin connector (2x3). It's not always easy to

figure out which end is which, so use a multimeter in continuity mode

to figure out which pin is ground. Once you're sure, mark your connector

so you'll know which pin is pin 1 (MISO, the pin opposite ground).

ISPs typically use a six-pin connector (2x3). It's not always easy to

figure out which end is which, so use a multimeter in continuity mode

to figure out which pin is ground. Once you're sure, mark your connector

so you'll know which pin is pin 1 (MISO, the pin opposite ground).

Once you have your ISP pins straight, refer to your handy-dandy

Atmega328 pinout and connect power, ground, MOSI, MISO, SCK, and RST

to the appropriate Atmega pins.

All wired up? In the Arduino IDE, set Programmer to your ISP,

for instance, USBtinyISP or Arduino as ISP

Then use the Upload button to upload sketches.

If you prefer Arduino-mk instead of the IDE, add this to your Makefile:

ISP_PROG = usbtiny

(or whatever ISP you're using). Then type

make ispload

instead of

make upload

Once you have your FTDI or ISP working, then you can think about making

an even simpler circuit -- without the external clock and its associated

capacitors. But there are a couple of additional tricks to that.

Stay tuned for Part 2.

Tags: hardware, arduino, maker

[

15:44 Dec 09, 2017

More hardware |

permalink to this entry |

]

Wed, 29 Nov 2017

Having written a basic blink program in C for

my

ATtiny85 with a USBtinyISP (Part 1), I wanted to use it to control other

types of hardware. That meant I wanted to be able to use Arduino libraries.

The Arduino IDE

I normally use Makefiles, but the Arduino IDE is much better supported

so I tried that first. I followed the steps at

High-Low

Tech: Programming an ATtiny w/ Arduino 1.6 (or 1.0).

But the short summary is:

- Run the Arduino IDE

- File->Preferences

- In "Additional Boards Manager" near the bottom, paste this:

https://raw.githubusercontent.com/damellis/attiny/ide-1.6.x-boards-manager/package_damellis_attiny_index.json

and click OK

- Tools->Boards->Board Manager...

- Find the ATTiny entry, click on it, and click Install

- Back in the main Arduino IDE, Tools->Boards should now havea

couple of Attiny entries. Choose the one that corresponds to your

ATTiny; then, under Processor, narrow it down further.

In

Tools->Programmer, choose the programmer you're using

(for example,

USBtinyISP).

Now you should be able to Verify and Upload a blink sketch

just like you would to a regular Arduino, subject to the pin limitations

of the ATTiny.

That worked for blink. But it didn't work when I started adding libraries.

Since the command-line was what I really cared about, I moved on rather

than worrying about libraries just yet.

ATtiny with Arduino-Makefile

For most of my Arduino development I use an excellent package called

Arduino-Makefile.

There's a Debian package called arduino-mk that works fine for normal

Arduinos, but for ATtiny, there have been changes, so use the version

from git.

A minimal blink Makefile looks like this:

BOARD_TAG = uno

include /usr/share/arduino/Arduino.mk

It assumes that if you're in a directory called blink, it

should compile a file called blink.ino. It will also build

any additional .cpp files it finds there. make upload

uploads the code to a normal Arduino.

With Attiny it gets quite a bit more complicated.

The key is that you have to specify an alternate core:

ALTERNATE_CORE = ATTinyCore

But there are lots of different ATtiny cores, they're all different,

and they each need a different set of specifiers like BOARD_TAG in

the Makefile. Arduino-Makefile comes with an example, but it isn't

very useful since it doesn't say where to get the cores that correspond

with the various samples. I ended up filing a documentation bug and

exchanging some back-and-forth with the maintainer of the package,

Simon John, and here's what I learned.

First: as I mentioned earlier, you should use the latest git version

of Arduino-Makefile. The version in Debian is a little older and some

things have changed; while the older version can be made to work with

ATtiny, the recipes will be different from the ones here.

Second, the recipes for each core will be different depending on which

version of the Arduino software you're using. Simon

says he sticks to version 1.0.5 when he uses ATtinys, because newer

versions don't work as well. That may be smart (certainly he has a lot

more experience than I do), but I'm always hesitant to rely on

software that old, so I wanted to get things working with the latest

Arduino, 1.8.5, if i could, so that's what the recipes here will

reflect.

Third, as mentioned in Part 1, clock rate should be 1MHz, not 8MHz

as you'll see in a lot of web examples, so:

F_CPU = 1000000L

Fourth, uploading sketches. As mentioned in the last article, I'm using

a USBtinyISP. For that, I use ISP_PROG = usbtiny and

sketches are uploaded by typing make ispload rather than

the usual make upload. change that if you're usinga

different programmer.

With those preliminaries over:

I ended up getting two different cores working,

and there were two that didn't work.

Install the cores in subdirectories in

your ~/sketchbook/hardware directory. You can have multiple

cores installed at once if you want to test different cores.

Here are the recipes.

CodingBadly's arduino-tiny

This is the core that Simon says he prefers, so it's the one I'm going

to use as my default. It's at

https://github.com/Coding-Badly/arduino-tiny.git,

and also a version on Google Code. (Neither one has been updated since 2013.)

git clone it into your sketchbook/hardware.

Then either cp 'Prospective Boards.txt' boards.txt

or create a new boards.txt and copy from 'Prospective Boards.txt'

all the boards you're interested in (for instance, all the attiny85

definitions if attiny85 is the only attiny board you have).

Then your Makefile should look something like this:

ARDUINO_DIR = /path/to/arduino-1.8.5

BOARD_TAG = attiny85at8

ALTERNATE_CORE = tiny

F_CPU = 1000000L

ISP_PROG = usbtiny

include /path/to/Arduino-Makefile/Arduino.mk

If your Arduino software is installed in /usr/share/arduino you can

omit the first line.

Now copy blink.ino -- of course, you'll have to change pin 13

to be something between 1 and 6 since that's how many pins an ATtiny

has -- and try make and make ispload.

SpenceKonde's ATTinyCore

This core is at https://github.com/SpenceKonde/ATTinyCore.git.

I didn't need to copy boards.txt or make any other changes,

just clone it under sketches/hardware and then use this Makefile:

ARDUINO_DIR = /path/to/arduino-1.8.5

ALTERNATE_CORE = ATTinyCore

BOARD_TAG = attinyx5

BOARD_SUB = 85

F_CPU = 1000000L

ISP_PROG = usbtiny

include /path/to/Arduino-Makefile/Arduino.mk

Non-working Cores

There are plenty of other ATtiny cores around. Here are two that

apparently worked once, but I couldn't get them working with the

current version of the tools. I'll omit links to them to try to

reduce the probability of search engines linking to them rather

than to the more up-to-date cores.

Damellis's attiny (you may see this referred to as HLT after the

domain name, "Highlowtech"), on GitHub as

damellis/attiny,

was the first core I got working with Debian's older version of

arduino-mk and Arduino 1.8.4. But when I upgraded to the latest

Arduino-Makefile and Arduino 1.8.5, it no longer worked. Ironic since

an older version of it was the one used in most of the tutorials I

found for using ATtiny with the Arduino IDE.

Simon says this core is buggy: in particular, there are problems with

software PWM.

I also tried rexxar-tc's arduino-tiny.core2 (also on GitHub).

I couldn't get it to work with any of the Makefile or Arduino

versions I tried, though it may have worked with Arduino 1.0.

With two working cores, I can get an LED to blink.

But libraries are the point of using the Arduino framework ...

and as I tried to move beyond blink.ino, I found that

not all Arduino libraries work with ATtiny.

In particular, Wire, used for protocols like I2C to talk to all

kinds of useful chips, doesn't work without substantial revisions.

But that's a whole separate topic. Stay tuned.

Tags: hardware, arduino, programming, maker

[

19:06 Nov 29, 2017

More hardware |

permalink to this entry |

]

Thu, 02 Nov 2017

![[ATtiny85 and USBtinyISP programmer]](http://shallowsky.com/blog/images/hardware/img_1889sm.jpg) Arduinos are great for prototyping, but for a small, low-power,

cheap and simple design, an ATtiny chip seems like just the ticket.

For just a few dollars you can do most of what you could with an

Arduino and use a lot of the same code, as long as you can make do

with a little less memory and fewer pins.

Arduinos are great for prototyping, but for a small, low-power,

cheap and simple design, an ATtiny chip seems like just the ticket.

For just a few dollars you can do most of what you could with an

Arduino and use a lot of the same code, as long as you can make do

with a little less memory and fewer pins.

I've been wanting to try them, and recently I ordered a few ATtiny85 chips.

There are quite a few ways to program them. You can buy programmers

specifically intended for an ATtiny, but I already had a USBtinyISP,

a chip used to program Arduino bootloaders, so that's what I'll

discuss here.

Wiring to the USBtinyISP

![[ATtiny85 and USBtinyISP wiring]](http://shallowsky.com/blog/images/hardware/attiny-usbtinyISP_bb.jpg) The best reference I found on wiring was

Using USBTinyISP to program ATTiny45 and ATTiny85.

That's pretty clear, but I made my own Fritzing diagram, with colors,

so it'll be easy to reconstruct it next time I need it.

The colors I used:

The best reference I found on wiring was

Using USBTinyISP to program ATTiny45 and ATTiny85.

That's pretty clear, but I made my own Fritzing diagram, with colors,

so it'll be easy to reconstruct it next time I need it.

The colors I used:

| MISO

| yellow

| VCC | red

|

| SCK

| white

| MOSI | green

|

| RESET

| orange

or red/black

| GND | black

|

Programming the ATtiny in C

I found a couple of blink examples at

electronut.in,

Getting Started with ATtiny AVR programming,

and in a Stack Exchange thread,

How

to program an AVR chip in Linux

Here's some basic blink code:

#include <avr/io.h>

#include <util/delay.h>

int main (void)

{

// Set Data Direction to output on port B, pins 2 and 3:

DDRB = 0b00001000;

while (1) {

// set PB3 high

PORTB = 0b00001000;

_delay_ms(500);

// set PB3 low

PORTB = 0b00000000;

_delay_ms(500);

}

return 1;

}

Then you need a Makefile. I started with the one linked from the electronut

page above. Modify it if you're using a programmer other than a USBtinyISP.

make builds the program, and make install

loads it to the ATtiny. And, incredibly, my light started blinking,

the first time!

![[ATtiny85 pinout]](http://shallowsky.com/blog/images/hardware/attiny85-pinout.jpg) Encouraged, I added another LED to make sure I understood.

The ATtiny85 has six pins you can use (the other two are power and ground).

The pin numbers correspond to the bits in DDRB and PORTB:

my LED was on PB3. I added another LED on PB2 and made it alternate

with the first one:

Encouraged, I added another LED to make sure I understood.

The ATtiny85 has six pins you can use (the other two are power and ground).

The pin numbers correspond to the bits in DDRB and PORTB:

my LED was on PB3. I added another LED on PB2 and made it alternate

with the first one:

DDRB = 0b00001100;

[ ... ]

// set PB3 high, PB2 low

PORTB = 0b00001000;

_delay_ms(500);

// set PB3 low, PB2 high

PORTB = 0b00000100;

_delay_ms(500);

Timing Woes

But wait -- not everything was rosy. I was calling _delay_ms(500),

but it was waiting a lot longer than half a second between flashes.

What was wrong?

For some reason, a lot of ATtiny sample code on the web assumes the

chip is running at 8MHz. The chip's internal oscillator is indeed 8MHz

(though you can also run it with an external crystal at various

speeds) -- but its default mode uses that oscillator in "divide by

eight" mode, meaning its actual clock rate is 1MHz. But Makefiles

you'll find on the web don't take that into account (maybe because

they're all copied from the same original source). So, for instance,

the Makefile I got from electronut has

CLOCK = 8000000

If I changed that to

CLOCK = 1000000

now my delays were proper milliseconds, as I'd specified.

Here's my working

attiny85

blink Makefile.

In case you're curious about clock rate, it's specified by what are

called fuses, which sound permanent but aren't: they hold their

values when the chip loses power, but you can set them over and over.

You can read the current fuse settings like this:

avrdude -c usbtiny -p attiny85 -U lfuse:r:-:i -v

which should print something like this:

avrdude: safemode: hfuse reads as DF

avrdude: safemode: efuse reads as FF

avrdude: safemode: Fuses OK (E:FF, H:DF, L:62)

To figure out what that means, go to the

Fuse calculator,

scroll down to Current settings and enter the three values

you got from avrdude (E, H and L correspond to Extended, High and Low).

Then scroll up to Feature configuration

to see what the fuse settings correspond to.

In my case it was

Int. RC Osc. 8 Mhz; Start-up time PWRDWN/RESET; 6CK/14CK+

64ms; [CKSEL=1011 SUT=10]; default value

and Divide clock by 8 internally; [CKDIV8=0] was checked.

More on ports and pins

There's more info on ATtiny ports in

ATTiny

Port Manipulation (Part 1): PinMode() and DigitalWrite()

Nobody seems to have written much about AVR/ATTINY

programming in general. Symbols like PORTB and

functions like _delay_ms() come from files in

/usr/lib/avr/include/, at least on my Debian system.

There's not much there, so if you want library functions to handle

nontrivial hardware, you'll have to write them or find them somewhere else.

As for understanding pins, you're supposed to go to the datasheet and read it

through, all 234 pages. Hint: for understanding basics of reading from and

writing to ports, speed forward to section 10, I/O Ports.

A short excerpt from that section:

Three I/O memory address locations are allocated for each port, one

each for the Data Register - PORTx, Data Direction Register - DDRx,

and the Port Input Pins - PINx. The Port Input Pins I/O location is

read only, while the Data Register and the Data Direction Register are

read/write. However, writing a logic one to a bit in the PINx

Register, (comma sic) will result in a toggle in the

corresponding Data Register. In addition, the Pull-up Disable - PUD

bit in MCUCR disables the pull-up function for all pins in all ports

when set.

There's also some interesting information there about built-in pull-up

resistors and how to activate or deactivate them.

That's helpful, but here's the part I wish they'd said:

PORTB (along with DDRB and PINB) represents all six pins. (Why B? Is

there a PORTA? Not as far as I can tell; at least, no PORTA is

mentioned in the datasheet.) There are six output pins, corresponding

to the six pins on the chip that are not power or ground. Set the bits

in DDRB and PORTB to correspond to the pins you want to set. So if you

want to use pins 0 through 3 for output, do this:

DDRB = 0b00001111;

If you want to set logical pins 1 and 3 (corresponding to pins 6 and 2

on the chip) high, and the rest of the pins low, do this:

PORTB = 0b00001010;

To read from pins, use PINB.

In addition to basic functionality, all the pins have specialized

uses, like timers, SPI, ADC and even temperature measurement (see the

diagram above). The datasheet goes into more detail about how to get

into some of those specialized modes.

But a lot of those specialties are easier to deal with using

libraries. And there are a lot more libraries available for the Arduino

C++ environment than there are for a bare ATtiny using C.

So the next step is to program the ATtiny using Arduino ...

which deserves its own article.

Tags: hardware, arduino, programming, maker

[

18:01 Nov 02, 2017

More hardware |

permalink to this entry |

]

Mon, 04 Sep 2017

![[Raspberry Pi Zero W]](http://shallowsky.com/blog/images/pi-no-headers.jpg) My new book is now shipping! And it's being launched via a terrific Humble

Bundle of books on electronics, making, Raspberry Pi and Arduino.

My new book is now shipping! And it's being launched via a terrific Humble

Bundle of books on electronics, making, Raspberry Pi and Arduino.

Humble Bundles, if you haven't encountered them before, let you pay

what you want for a bundle of books on related subjects. The books are

available in ePub, Mobi, and PDF formats, without DRM, so you can read

them on your choice of device. If you pay above a certain amount,

they add additional books. My book is available if you pay $15 or more.

You can also designate some of the money you pay for charity.

In this case the charity is Maker Ed,

a crowdfunding initiative that supports Maker programs primarily

targeted toward kids in schools. (I don't know any more about them

than that; check out their website for more information.)

Jumpstarting the Raspberry Pi Zero W is a short book,

with only 103 pages in four chapters:

- Getting Started: includes tips on headless setup and the Linux

command line;

- Blink an LED: includes ways to blink and fade LEDs from the shell

and from several different Python libraries;

- A Temperature Notifier and Fan Control: code and wiring

instructions for three different temperature sensors (plus humidity

and barometric pressure), and a way to use them to control your house

fan or air conditioner, either according to the temperature in the room

or through a Twitter command;

- A Wearable News Alert Light Show: wire up NeoPixels or DotStars

and make them respond to keywords on Twitter or on any other web page

you choose, plus some information on powering a Pi portably with batteries.

All the code and wiring diagrams from the book, plus a few extras, are

available on Github, at my

Raspberry Pi Zero

Book code repository.

To see the book bundle, go to the

Electronics

& Programming Humble Bundle and check out the selections.

My book, Jumpstarting the Raspberry Pi Zero W, is available if

you pay $15 or more -- along with tons of other books you'll probably

also want. I already have Make: Electronics and it's one of the

best introductory electronics books I've seen, so I'm looking forward

to seeing the followup volume. Plus there are books on atmospheric and

environmental monitoring, a three-volume electronic components

encyclopedia, books on wearable electronics and drones and other cool stuff.

I know this sounds like a commercial, but this bundle really does look

like a great deal, whether or not you specifically want my Pi book,

and it's a limited-time offer, only good for six more days.

Tags: writing, raspberry pi, electronics, maker, arduino

[

13:21 Sep 04, 2017

More writing |

permalink to this entry |

]

Wed, 16 Jul 2014

![[Arduino intervalometer]](http://shallowsky.com/blog/images/hardware/img_6213-450.jpg) While testing my

automated critter

camera, I was getting lots of false positives caused by clouds

gathering and growing and then evaporating away. False positives

are annoying, but I discovered that it's fun watching the clouds grow

and change in all those photos

... which got me thinking about time-lapse photography.

While testing my

automated critter

camera, I was getting lots of false positives caused by clouds

gathering and growing and then evaporating away. False positives

are annoying, but I discovered that it's fun watching the clouds grow

and change in all those photos

... which got me thinking about time-lapse photography.

First, a disclaimer: it's easy and cheap to just buy an

intervalometer. Search for timer remote control

or intervalometer and you'll find plenty of options for

around $20-30. In fact, I ordered one.

But, hey, it's not here yet, and I'm impatient.

And I've always wanted to try controlling a camera from an Arduino.

This seemed like the perfect excuse.

Why an Arduino rather than a Raspberry Pi or BeagleBone? Just because

it's simpler and cheaper, and this project doesn't need much compute

power. But everything here should be applicable to any microcontroller.

My Canon Rebel Xsi has a fairly simple wired remote control plug:

a standard 2.5mm stereo phone plug.

I say "standard" as though you can just walk into Radio Shack and buy

one, but in fact it turned out to be surprisingly difficult, even when

I was in Silicon Valley, to find them. Fortunately, I had found some,

several years ago, and had cables already wired up waiting for an experiment.

The outside connector ("sleeve") of the plug is ground.

Connecting ground to the middle ("ring") conductor makes the camera focus,

like pressing the shutter button halfway; connecting ground to the center

("tip") conductor makes it take a picture.

I have a wired cable release that I use for astronomy and spent a few

minutes with an ohmmeter verifying what did what, but if you don't

happen to have a cable release and a multimeter there are plenty of

Canon

remote control pinout diagrams on the web.

Now we need a way for the controller to connect one pin of the remote

to another on command.

There are ways to simulate that with transistors -- my

Arduino-controlled

robotic shark project did that. However, the shark was about a $40

toy, while my DSLR cost quite a bit more than that. While I

did find several people on the web saying they'd used transistors with

a DSLR with no ill effects, I found a lot more who were nervous about

trying it. I decided I was one of the nervous ones.

The alternative to transistors is to use something like a relay. In a relay,

voltage applied across one pair of contacts -- the signal from the

controller -- creates a magnetic field that closes a switch and joins

another pair of contacts -- the wires going to the camera's remote.

But there's a problem with relays: that magnetic field, when it

collapses, can send a pulse of current back up the wire to the controller,

possibly damaging it.

There's another alternative, though. An opto-isolator works like a

relay but without the magnetic pulse problem. Instead of a magnetic

field, it uses an LED (internally, inside the chip where you can't see it)

and a photo sensor. I bought some opto-isolators a while back and had

been looking for an excuse to try one. Actually two: I needed one for

the focus pin and one for the shutter pin.

How do you choose which opto-isolator to use out of the gazillion

options available in a components catalog? I don't know, but when I

bought a selection of them a few years ago, it included a 4N25, 4N26

and 4N27, which seem to be popular and well documented, as well as a

few other models that are so unpopular I couldn't even find a

datasheet for them. So I went with the 4N25.

Wiring an opto-isolator is easy. You do need a resistor across the inputs

(presumably because it's an LED).

380Ω

is apparently a good value for the 4N25, but

it's not critical. I didn't have any 380Ω but I had a bunch of

330Ω so that's what I used. The inputs (the signals from the Arduino)

go between pins 1 and 2, with a resistor; the outputs (the wires to the

camera remote plug) go between pins 4 and 5, as shown in

the diagram on this

Arduino

and Opto-isolators discussion, except that I didn't use any pull-up

resistor on the output.

Then you just need a simple Arduino program to drive the inputs.

Apparently the camera wants to see a focus half-press before it gets

the input to trigger the shutter, so I put in a slight delay there,

and another delay while I "hold the shutter button down" before

releasing both of them.

Here's some Arduino code to shoot a photo every ten seconds:

int focusPin = 6;

int shutterPin = 7;

int focusDelay = 50;

int shutterOpen = 100;

int betweenPictures = 10000;

void setup()

{

pinMode(focusPin, OUTPUT);

pinMode(shutterPin, OUTPUT);

}

void snapPhoto()

{

digitalWrite(focusPin, HIGH);

delay(focusDelay);

digitalWrite(shutterPin, HIGH);

delay(shutterOpen);

digitalWrite(shutterPin, LOW);

digitalWrite(focusPin, LOW);

}

void loop()

{

delay(betweenPictures);

snapPhoto();

}

Naturally, since then we haven't had any dramatic clouds, and the

lightning storms have all been late at night after I went to bed.

(I don't want to leave my nice camera out unattended in a rainstorm.)

But my intervalometer seemed to work fine in short tests.

Eventually I'll make some actual time-lapse movies ... but that will

be a separate article.

Tags: arduino, hardware, photography, intervalometer, time-lapse, maker

[

18:31 Jul 16, 2014

More hardware |

permalink to this entry |

]

Wed, 18 Sep 2013

I found myself wanting to upload a sketch to an Arduino Pro Mini

recently, using an FTDI

Friend, and found that how to do it was surprisingly undocumented.

![[Arduino Pro Mini]](http://shallowsky.com/blog/images/arduino/ArduinoProMini.jpg)

![[Arduino Pro Mini]](http://shallowsky.com/blog/images/arduino/ftdi-friend.jpg)

First, the important thing is that the six FTDI pins do match up with

the six pins at the edge of the Pro Mini, though obviously you have

to figure out which way to rotate the two boards so you won't be 180

degrees off. I wasn't clear on that since the labels on the pins

don't seem to match (see below).

Second, if you haven't soldered headers to your Pro Mini, you can

stick a female-female header into the FTDI Friend's female header.

then insert the other side of the header into the holes in the Pro

Mini at an angle -- hold them with some tension so that the header

pins are making contact with the copper-plated rims of the Pro Mini

holes.

Okay, so the big question is which way to match the pins.

It's complicated by the Pro Mini's having both outer holes unlabeled.

Usually when trying to match pins I start by looking for Ground,

and make sure the two Grounds match. That doesn't work here --

the FTDI has the Gnd on one of the outer pins, while the

Pro Mini has Gnd on the second pin in. The pin parked Gnd on the Pro

Mini goes to CTS on the FTDI, while the pin parked Gnd on the FTDI

corresponds to a pin on the Pro Mini that's unmarked.

If you turned one of them 180 degrees, then you'd have Gnd (Pro Mini)

- Rx (FTDI), and Gnd (FTDI) - unmarked (Pro Mini). No help there.

So ignore Ground and use VCC as your guide. It's on the third pin in --

so only in one orientation will VCC on both boards match. That's the

orientation you want, and it works.

On some Pro Minis and some FTDI boards, you'll also have a label for

"GREEN" or "GRN" on one side, and "BLACK" or "BLK" on the other.

Match those if you have them, but you may not find that on all boards,

particularly if you ever hook up to clone or third-party boards.

So stick to VCC as a guide and you should be okay.

So what are those outer two holes on the Pro Mini?

An image search for

Arduino Pro Mini Pinout gives some pages showing GRN as

TX and BLK as +9V (I assume that would be Vin, but actually those pages

seem to be referring to the Arduino Mini, not the Pro Mini).

But another shows GRN as RESET and BLK as Gnd.

The official

Pro Mini schematic shows the outer pins on JP1 as DTR and GND.

So that seems most likely.

Tags: arduino, hardware, maker

[

16:28 Sep 18, 2013

More hardware |

permalink to this entry |

]

Sat, 29 Jun 2013

![[GetSET Robots and Sensors workshop]](http://shallowsky.com/blog/images/getset2013/img_7756.jpg) Wednesday I taught my "Robotics and Sensors" workshop at

the SWE GetSET summer camp.

Wednesday I taught my "Robotics and Sensors" workshop at

the SWE GetSET summer camp.

It was lots of fun, and definitely better than last year. It helped that

I had a wonderful set of volunteers helping out -- five women from

CodeChix (besides myself), so we had

lots of programming expertise, plus a hardware engineer who was

wonderfully helpful with debugging circuits. Thanks so much to all the

volunteers! You really made the workshop!

We also had a great group of girls -- 14 high school seniors, all smart

and motivated, working in teams of two.

How much detail?

One big issue when designing a one-day programming workshop is how

much detail to provide in each example, and how much to leave to the

students to work out. Different people learn differently. I'm the sort

who learns from struggling through a problem, not from simply copying

an example, and last year I think I erred too much in that direction,

giving minimal information and encouraging the girls to work out the rest.

Some of them did fine, but others found it frustrating. In a one-day

workshop, if you have to spend too much time working everything out,

you might never get to the fun stuff.

So this year I took a different approach. For each new piece of hardware,

I gave them one small, but complete, working example, then suggested

ways they could develop that. So for the first example

(File->Examples->Basic->Blink is everyone's first

Arduino exercise), I gave everyone two LEDs and two resistors, and

as soon as they got their first LED blinking, I encouraged them to

try adding another.

It developed that about half the teams wired their second

LED right next to the first one, still on pin 13. Clever! but not what

I'd had in mind.

So I encouraged them to try moving the second LED to a different pin,

like pin 12, and see if they could make one LED turn on while the

other one turned off.

Another challenge with workshops is that people work at very different

speeds. You have to have projects the fast students can work on to keep them

from getting bored while the rest are catching up. So for LEDs, having

a box full of extra LEDs helped, and by the time we were ready to move on,

they had some great light shows going -- tri-colored blinkers, fast

flashers, slow double-blinks.

I had pushbuttons on the tentative agenda but I was pretty sure that

we'd skip that part. Pushbuttons are useful but they aren't really all

that much fun. You have to worry about details like pull-down resistors

and debouncing, too much detail when you have only six hours total.

Potentiometers are more rewarding. We went through

File->Examples->03.Analog->AnalogInput,

and a few teams also tried LED fading with

File->Examples->03.Analog->AnalogInOutSerial.

Music

![[GetSET Robots and Sensors workshop]](http://shallowsky.com/blog/images/getset2013/img_7761.jpg) But then we moved on to what was really the highlight of the day,

piezo speakers.

Again, I provided a small working

example

program to create a rising tone. The Arduino IDE has no good

speaker examples built in, so I'd made a short url for my

Robots and Sensors

workshop page,

But then we moved on to what was really the highlight of the day,

piezo speakers.

Again, I provided a small working

example

program to create a rising tone. The Arduino IDE has no good

speaker examples built in, so I'd made a short url for my

Robots and Sensors

workshop page, is.gd/getset, to make it easyto

copy/paste code. It took no time at all before their speakers were

making noise.

I was afraid they'd just stop there ...

but as it turned out, everybody was energized

(including me and the other volunteers) by all the funny noises,

and without any prompting the girls immediately got to work changing

their tones, making them rise faster or slower, or (with some help

from volunteers) making them fall instead of rise. Every team had

different sounds, and everybody was laughing and having fun as they

tweaked their code.

In fact, that happened so fast that we ended up with plenty of time

left before lunch. My plan was to do speakers right before lunch because

noise is distracting, and after you've done that you can't to

concentrate on anything else for a while. So I let them continue to

play with the speakers.

I was glad I did. At least three different teams took the initiative

to search the web and find sample code for playing music.

There were some hitches -- a lot of the code samples needed to be

tweaked a bit, from changing the pin where the speaker was plugged in,

to downloading an include file of musical notes. One page gave code

that didn't compile at all. But it was exciting to watch -- after all,

this sort of experimentation and trial-and-error is a big part

of what programmers do, and they all eventually got their music projects

working.

One thing I learned was that providing a complete working

.ino file makes a big difference. Some of the "music on Arduino"

pages the girls found provided C functions but no hints as to how

to call those functions. (It wasn't obvious to me, either.)

Some of my own examples for the afternoon projects were like that,

providing code snippets without setup() and loop(), and some teams

were at sea, unsure how to create setup() and loop(). Of course

I'd explained about setup() and loop() during the initial blink

exercise. But considering how much material we covered in such a short

time, it's not reasonable to expect everybody to remember details like

that. And the Arduino IDE error messages aren't terribly easy to read,

especially showing up orange on black in a tiny 3-line space at the

bottom of the window.

So, for future workshops, I'll provide complete .ino files for all my

own examples, plus a skeleton file with an empty setup() and loop()

already there.

It's okay to spoon feed basic details like the structure of an .ino

file if it gives the students more time to think about the really

interesting parts of their project.

Afternoon projects

![[Working on the robotic car]](http://shallowsky.com/blog/images/getset2013/img_7766.jpg) After lunch, the afternoon was devoted to projects. Teams could pick

anything we had hardware for, work on it throughout the afternoon and

present it at the end of the workshop. There were two teams working on

robotic cars (sadly, as with so many motor projects, the hardware

ended up being too flaky and the cars didn't do much).

Other teams worked with sonar rangefinders, light sensors or tilt

switches, while some continued to work on their lights and music.

After lunch, the afternoon was devoted to projects. Teams could pick

anything we had hardware for, work on it throughout the afternoon and

present it at the end of the workshop. There were two teams working on

robotic cars (sadly, as with so many motor projects, the hardware

ended up being too flaky and the cars didn't do much).

Other teams worked with sonar rangefinders, light sensors or tilt

switches, while some continued to work on their lights and music.

Everybody seemed like they were having a good time, and I'd seen a lot of

working (or at least partly working) projects as I walked around

during the afternoon, but when it came to present what they'd done,

I was a little sad.

There was a lot of "Well, I tried this, but I couldn't get it to work,

so then I switched to doing this." Of course, trying things and

changing course are also part of engineering ... that sentence

describes a lot of my own playing with hardware, now that I think of

it. But still ... I was sad hearing it.

Notes for next time

So, overall, I was happy with the workshop. I haven't seen the evaluation

forms yet, but it sure seemed like everybody was having fun,

and I know we volunteers did.

What are the points I want to remember for next time?

- Start with small but complete working examples to introduce each

new hardware component.

- Provide complete .ino files, not just code snippets.

- Skip pushbuttons, but do try to cover AnalogInOutSerial and PWM output.

Or at least have printed handouts explaining the PWM outputs and LED fading.

- Turnkey kits are good: the less "connect the blue wire to pin 7,

the green one to pin 8" the better. For things like cars, I'd

like something already wired up with battery and shield,

"Just add Arduino".

- Keep a closer eye on the afternoon projects -- try to make sure

each team has something they're proud to show off.

Thanks again to the great volunteers! I'm looking forward to giving

this workshop again.

Tags: robots, arduino, education, hardware, programming, maker

[

20:36 Jun 29, 2013

More education |

permalink to this entry |

]

Sun, 23 Jun 2013

![[Servo wired up to Arduino, without separate battery]](http://shallowsky.com/arduino/class/servo-wired.jpg) My quest to make physical things move with Arduinos continues as we

ramp up to Wednesday's GetSET workshop.

My quest to make physical things move with Arduinos continues as we

ramp up to Wednesday's GetSET workshop.

A few nights ago I finally broke out some old airplane servos and

hooked them up to the Arduino. Don't know why I'd never gotten around

to that, but I hadn't.

I had to decode the wire colors, aided by this excellent

Connector

Types page from Servo City. The GWS Naro servo I chose, with a

JR plug, has a red wire (power), a brown wire (ground) and an orange

wire (signal). Easy enough.

The Arduino software has a built-in

Servo library,

with instructions on wiring things up and a sample "Sweep" program

to run the servo through its paces. Easy. I hooked it up and in just a

few minutes I had the servo arm sweeping. Servos are so easy!

Or so I thought.

The next day, I tried turning it into a real application, and

that's where my problems started. I added a couple of photoresistors

to my basic servo circuit and wrote a quick sketch to hook up the servo

and print the output from the photoresistors to the serial port,

as a first step before making it actually move the servos in response

to the light coming in.

And ... nothing. Not only did I not get any output on my serial

console, but I couldn't even open the serial console -- /dev/ttyACM0

didn't exist on my computer, or if it did, I got an error trying to

open it. I couldn't even download new versions of the sketch,

since those, too, are downloaded over the ACM0 serial device.

It turns out that servos, like larger motors, need a separate power

source. Sometimes you can get away with powering them from the

Arduino's 5v supply, but sometimes it will lead to flaky results.

This is contrary to every tutorial I found on the web.

The official Arduino.cc

Servo library documentation says

"The power wire is typically red, and should be connected to the 5V

pin on the Arduino board."

and adds

"Note that servos draw considerable power, so if you need to drive

more than one or two, you'll probably need to power them from a

separate supply (i.e. not the +5V pin on your Arduino). Be sure to

connect the grounds of the Arduino and external power supply together."

And the Adafruit motor

shield documentation says,

"Servos are powered off of the same regulated 5V that the Arduino

uses. This is OK for the small hobby servos suggested. If you want

something beefier, cut the trace going to + on the servo connectors

and wire up your own 5-6V supply!"

Basically, everywhere you turn people will tell you that for one or two

servos, there's no point in fussing with a separate power supply.

But when I went to the #arduino IRC channel, the experts there assured

me that all the web tutorials were wrong, and that power was almost

certainly my problem -- even with a single tiny GWS Naro servo.

And sure enough, when I added a 7.4v li-po battery as the power source

for the servo, all my problems went away. Serial communication worked

fine, and the servo was less jumpy. It's probably less risky to the

Arduino, too.

The weirdest part of all this? When I tried to power it all off the

Arduino's power supply (from USB), the servo was working fine, moving

to wherever I told it. It was just serial communications to the PC

that was failing.

I still have yet to find a good, simple way to power servos

if you can't power them off the Arduino's 5v supply.

Apparently their maximum voltage is 6V, and it's risky giving them

any more than that.

Right now I have a 7.4V li-po pack going through a speed controller;

I'm not using the speed controller for anything except voltage regulation.

Pretty silly.

I tried using a 4 AA pack, but that didn't seem to have enough oomph

to power the servos. Maybe the answer is to add a 5v voltage regulator

to the circuit, but that makes it a little difficult for robotics classes.

So, anyway, don't believe what you read on the net. That little 5v port

is not a reliable power source even for one small hobby servo.

Spread the word! And have fun playing with servos, whatever you end

up using as a power source.

Tags: arduino, hardware, maker

[

21:43 Jun 23, 2013

More hardware |

permalink to this entry |

]

Thu, 30 May 2013

Last summer I led a

one day robotics workshop

for high school girls

as part of the Society of Women Engineers'

GetSET summer camp.

I'm giving it again this year, on June 26.

We're still lining up volunteers to help teach the workshop,

and I'd love help from bay area women -- you don't have to be a

robotics or programming expert, just willing to learn and play.

The workshop is based around the

Arduino open-source

microcontroller: we hook up Arduinos, then wire up LEDs, buzzers

and other parts on breadboards and make them do things.

It's a programming workshop as well as a hardware one:

most of the girls had a workshop the previous summer on

Ruby programming,

but that's their only exposure to programming.

So it's a challenge to see how much we can cover in one day --

and a testament to the girls that they do so well.

Last year we spent the morning covering wiring Arduinos to the basics

like breadboards, LEDs, pushbuttons and potentiometers. Then in the

afternoon, teams worked on projects --

some of them wired together lots of colored LEDs, some worked with

making sounds with buzzers, and one team built a robotic truck.

I was hoping to be able to show them more motorized projects,

and I'd brought several toy cars and trucks scavenged from thrift

shops (radio controlled toys that had lost their radio controller).

But

the

wiring needed for the H-bridge to control the motor is complex,

and the team that chose the truck project had their hands full getting

the truck running by the end of the day -- forget about adding

any bells and whistles. I wanted to make that easier.

![[Homemade, super cheap Arduino motor shield]](http://shallowsky.com/blog/images/hardware/motorshield/motorshield1T.jpg)

So for this year, with a little more time to prepare,

I'm wiring up some Arduino motor shields.

Shields are devices that stack on top of an Arduino. You can do all

the difficult wiring beforehand, and just plug in the shield when you're

ready to use it. The down side is that shields can be expensive --

motor shields typically cost around $25. That's okay if you're buying

one, but if you're trying to outfit a classroom, that can add up

pretty quickly.

But I found a way of building motor shields cheaply. The H-bridge chip

I'm using, the

SN754410, is $1.75 at Jameco

if you buy 5 or more.

Jameco also carries a proto-shield

PC board

($4.25 in quantity) and

stacking

headers ($1.59). So that's only $7.59 per shield, plus shipping,

not counting a few sundries like battery connectors that I'd already

bought for last year's class.

Then I had to wire up the shields. I was all fired up about having a

good excuse to use wire-wrap instead of soldering. But then I realized

that tiny 30-gauge wire-wrap wire probably wasn't adequate for the current

going to the motors. So I soldered wires for the motors,

the power lines from the battery connector to the H-bridge chip,

and from the battery connector to the Arduino's Vin.

Then I wire-wrapped everything else.

![[Car sporting super cheap Arduino motor shield]](http://shallowsky.com/blog/images/hardware/motorshield/car-motorshieldT.jpg)

The end result looks nice and clean from the top (please avert your

eyes from my messy soldering underneath). There's no scary rats-nest

of wires, like with the breadboards I used last year, and there's plenty

of empty space on the board to velcro a battery or attach sensors like

an ultrasonic rangefinder. I think this will work well and will

encourage the girls to get some little cars zipping around the

computer room.

I'm looking forward to setting up some simple projects I can

combine with the cars -- light sensors, sonar or IR rangefinders,

other ideas? I'd love suggestions from anybody, and I'd especially

love to line up some volunteers (women only for the day of the

workshop, please).

Workshop day -- June 26 -- mostly means walking around checking on how

the girls are doing, cheering them on, helping them debug problems by

checking their wiring and looking over their programs (very simple

code -- remember, they've never seen C code before).

And if anybody (male or female) wants to get together before the

workshop and play with Arduinos, help me solder the rest of the shields,

and brainstorm fun projects for the girls, please drop me a line!

The rough outline, handouts and wiring diagrams so far are at my

Robots and Sensors Workshop

page.

Tags: arduino, hardware, robots, maker

[

19:40 May 30, 2013

More hardware |

permalink to this entry |

]

Sun, 17 Feb 2013

I've done a few experiments with

playing

music on an Arduino over the years -- the Arduino library has a

tone() call that gives you a nice tinny monophonic

"chiptunes" style noise. But for playing anything more complex,

you need more processing power.

I had a silly little project in mind. I like some pink noise when I'm

sleeping (in summer, I usually have a fan running). You can buy

electronic devices called "sleep soothers" that have tracks of the

ocean, rain, trains etc. but they often have annoying misfeatures

(like foghorns or train whistles in the middle of a track). Wouldn't

it be more fun to make my own, with sound samples of my choice?

Pink noise samples

Of course, I needed some sound samples, and

I found a great resource: Laptop.org's list of

Free sound samples.

I downloaded a few sample collections that looked like they might have

some nice ambient pink-noise sounds -- rain, ocean and so forth.

Some of the samples were usable right away.

But others are only available at 44.1k, and the

Adafruit Wave Shield, the hardware I was targeting first, will only play

WAV audio at 16k. So they needed to be converted.

A simple shell loop did that:

for fil in *.wav ; do

avconv -i $fil -ar 16000 ../samples16/$fil

echo $fil

done

Arduino hardware

There are several Arduino shields for playing sound files.

The simplest (and probably cheapest) is the

Adafruit Wave Shield,

and that's what I started with. It comes as a kit that you solder

together (an easy soldering project) and it has its own volume control

and SD card reader. On the down side, it can only play .WAV files, not

other formats like .MP3 or .OGG. But for my sleep soother project that

was okay.

Getting basic sounds playing was easy, following Adafruit's tutorial

and sample code. But for my project, I also needed some external

buttons, to allow for jumping from one track to the next. I was a

little confused about which pins are used by the shield, and I ended

up wiring my button to one of the pins that the shield uses for

talking to the SD card reader. Things didn't work at all. And then

while I was fumbling with plugging/unplugging things, at some point

I installed the shield onto the Arduino wrong, with the pins off by one.

I'm not sure whether it was the miswired button or the off-by-one shield,

but something got fried in the wave shield and it was never able to

read an SD card again after that (yes, even after plugging it in properly).

I thought about ordering another Wave Shield. But I was leery -- if

it's so delicate that a stray 5v signal in the wrong place can fry it

permanently, how long did I expect a second one to last? Besides, I was

tired of soldering things, and I happened to be putting in an Amazon

order for some other things. So I ran a search and found that there was

an MP3 player shield available through them, made by Seeed Studio.

It even had buttons built in, so I wouldn't need any extra hardware.

It was a little more expensive than the Wave shield, but it claimed to

play MP3 and OGG as well as WAV, and it comes pre-assembled, no

soldering needed.

The hardware arrived and looked nice. Two simple buttons plus a

"multifunction" button you can press or rock left or right. I grabbed

a micro SD card, put some MP3s on it, and went to

Seeed's page

on the Music Shield.

Hacking the Seeed library

I was a little worried when I discovered that they have three

different demos there -- each of which comes with a different library,

and you have to remove one set of libraries before you can try a

different demo. Not a good sign.

And indeed, it wasn't. None of the demos worked at all. When I added

some debug Serial.printlns, I found that it wasn't opening

the SD card.

Much web searching found a couple of people saying they'd discovered that

the Seeed shield only works with 2G or smaller microSD cards. Good luck

finding one of those! The next day, I drove all over town looking for

one, without success, and was on the verge of giving up when Dave remembered a

little cheapie camera he'd bought a few years ago for taking airplane

movies. It came with a microSD card. Success! It was a 2G card.

Back to trying the various demos and their incompatible libraries again.

And this time, one of the demos, the first one (the one that comes with

the Music v1 14.zip library), worked. I could play tracks,

sequentially as they were loaded on the SD card.

Unfortunately, that wasn't what I wanted to do -- I wanted to play the

same track over and over, jumping to the next track when the user

presses a button. I tried the other demos. None of them worked at all.

Long story short, after struggling for the better part of a week and

reverse-engineering a fair amount of the Music v1 14 library, I finally

got my sketch working.

Sharing the changes

I come from the open-source world. I keep my

Arduino sketches on GitHub

(at least once they work well enough to be useful to anybody).

So of course I wanted to share the work I'd put into fixing this

library.

I had it all laid out and ready to commit, and was working on

some documentation on how to use it, when I noticed the readme.txt

in the library directory. It begins:

Copyright (c) 2010 Seedstudio. All right reserved.

Pffft! So after finally getting things working, I can't share my working

version of the library! What are they thinking? What on earth is the

point of distributing a library for your hardware, one that you know

doesn't work very well (or you wouldn't be distributing four different

incompatible versions of it), and then not letting anyone fix it for you?

I posted a query in one of the many

threads

discussing problems with the Music Shield, asking if Seeed would

consider releasing the library under a license that allowed redistribution.

It's been a few weeks now, and no answer yet.

Incidentally, even posting the query wasn't easy. Seeed doesn't let

you post in their forums unless you register -- and the registration

process requires full name, address, and phone number! Fortunately,

they have no way of knowing whether the info you give them is fake,